Why Retailers Are Rethinking Cycle Counts: From Periodic Counts to Continuous, Verified Inventory Accuracy

The Hidden Cost of Counting

Every retailer knows the drill.

An associate with a scanner walks aisle to aisle, counting cases and adjusting numbers while customers wait for help. It is a familiar sight, and a costly one.

Cycle counts have long been part of standard retail operations. They were designed to maintain accuracy between full physical inventories, helping teams reconcile what is on the shelf with what is in the system. But as retail complexity grows, the limits of this decades-old practice are becoming impossible to ignore.

Manual cycle counts consume valuable labor hours, interrupt normal operations, and often fail to deliver the accuracy today’s omnichannel environment demands.

That is why many retailers are beginning to rethink the way they track inventory accuracy, viewing it not as a scheduled task but as a continuous process.

The Problem With Traditional Cycle Counts

Despite their best efforts, most retailers still operate with surprisingly low inventory accuracy.

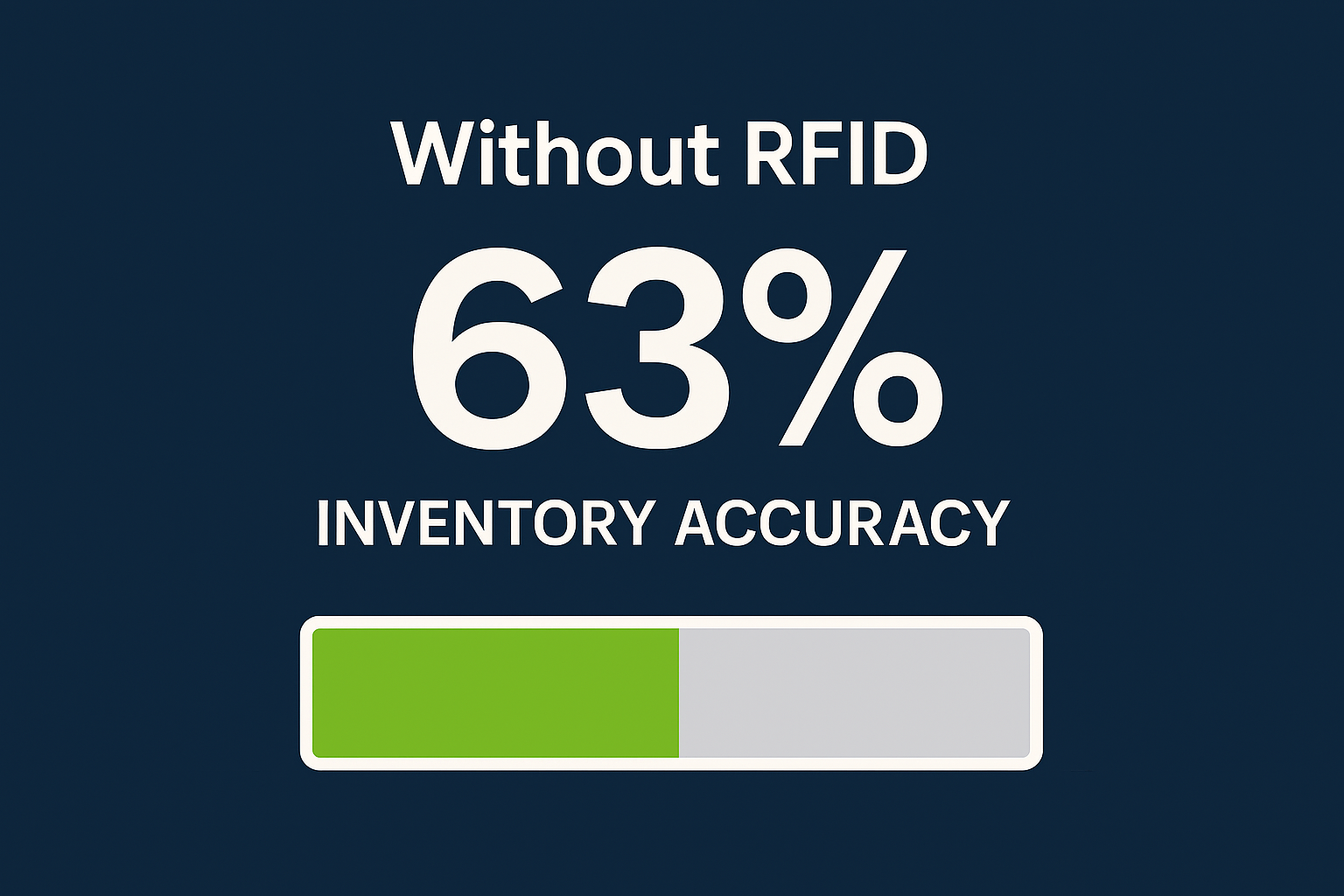

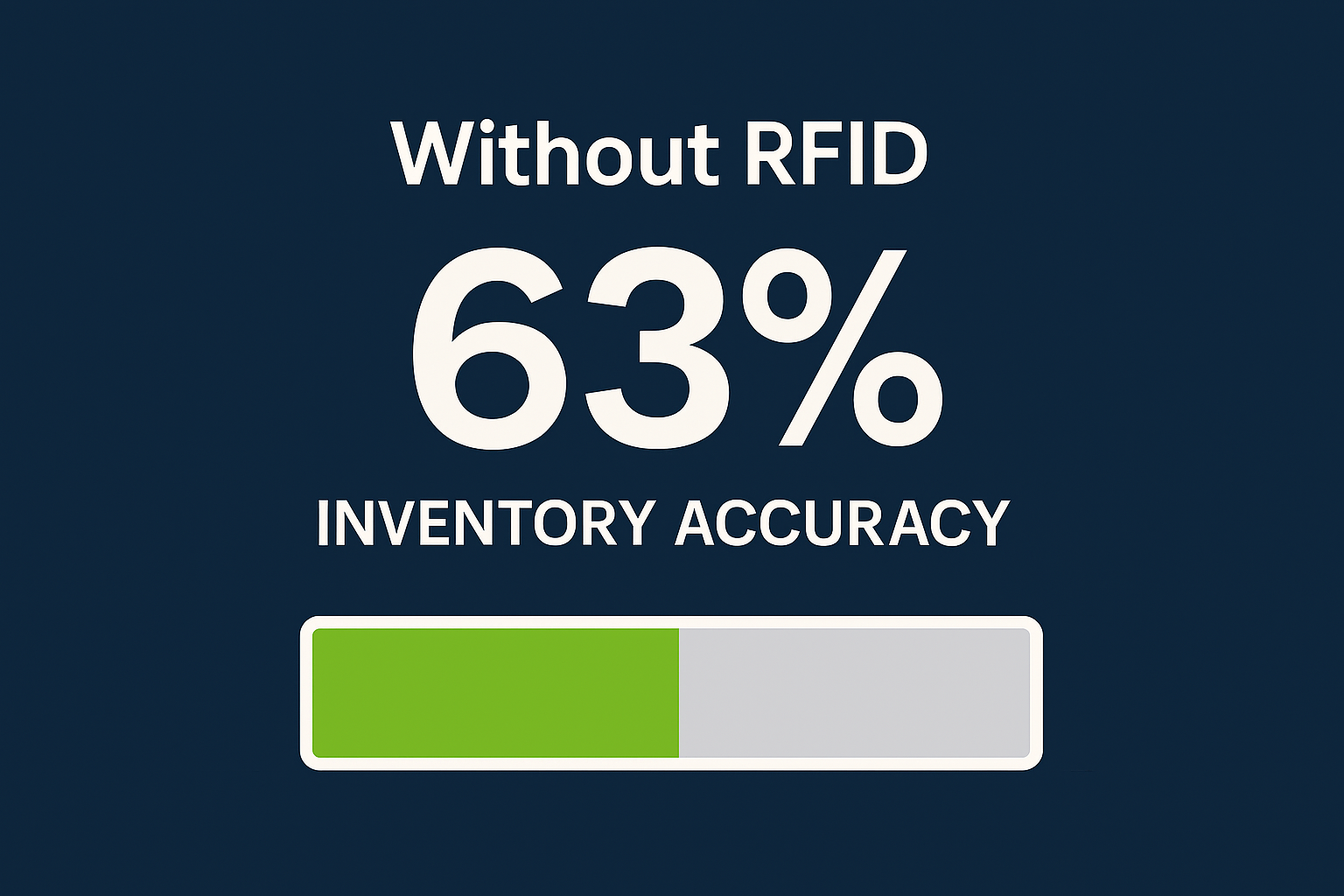

According to Auburn University’s RFID Lab, the average store-level accuracy rate without RFID technology sits around 63 percent. That means more than one in three items are either misplaced, miscounted, or missing entirely from the system view.

Cycle counts, while necessary, can only capture a moment in time. They are typically performed weekly or monthly, which means discrepancies can persist for days or weeks before they are discovered. By the time errors are corrected, the sale is often already lost.

The process also strains labor resources. Associates are pulled from higher-value tasks to scan shelves, reconcile variances, and restart the same process the following week.

In short, traditional cycle counts help retailers find problems, but they rarely solve them.

What Is Driving the Shift

Several forces are pushing retailers to rethink their approach to inventory visibility.

- Omnichannel complexity: With buy-online-pickup-in-store and ship-from-store models, accuracy gaps translate directly to missed sales and poor customer experiences.

- Labor shortages and rising costs: Teams are stretched thin, and manual counting no longer scales.

- Consumer expectations: Shoppers expect store and online availability data to match, and quickly lose trust when it does not.

- Data-driven operations: Retailers are increasingly relying on analytics and AI to inform decisions. Outdated or inaccurate inventory data undermines every insight built on it.

These pressures are leading to one clear conclusion: it is time to move from periodic verification to continuous visibility.

From Counting to Knowing

Leading retailers such as Walmart, Nordstrom, and Zara have expanded item-level RFID programs, while Kroger is rolling out RFID across departments in most of its 2,750 stores, including its Fred Meyer banner.

RFID eliminates line-of-sight scanning and enables near-instant updates when products move, sell, or restock. Studies from Auburn University’s RFID Lab and GS1 US show that retailers implementing RFID can achieve 95 percent or greater inventory accuracy while improving stock availability and sales.

But data alone is not enough. To keep information current, it must be verified continuously against what is happening on the shelf. That is where automation and computer vision come in.

Badger Technologies’ next-generation digital teammates combine RFID intelligence with image-based verification from Autonomous Mobile Robots (AMRs), creating a continuous feedback loop between digital records and physical reality.

As these autonomous systems scan store aisles, they read RFID tags, detect misplaced or missing items, and validate pricing and planogram compliance, giving retailers real-time, actionable visibility.

Instead of stopping operations to confirm what is on the shelf, retailers are letting the shelf confirm it for them.

The Benefits of Continuous Visibility

When cycle counts evolve into continuous verification, retailers see improvements across every level of their operation.

- Reduced labor burden: Associates spend less time scanning and more time serving customers.

- Faster replenishment: Real-time alerts flag gaps before they become out-of-stocks.

- Improved omnichannel fulfillment: Accurate, verified data ensures orders are filled correctly.

- Higher sales and loyalty: When shoppers can trust product availability, they return.

- Data-driven decision-making: Verified, high-quality data fuels better analytics, planning, and merchandising.

Just as important, continuous visibility strengthens the partnership between people and technology. Store teams are empowered with clearer priorities, actionable insights, and the freedom to focus on customer experience instead of manual verification.

In many cases, RFID and automation deliver measurable return on investment within months. Studies show sales uplift in RFID-enabled categories often falls between 5 and 15 percent, driven by higher product availability and improved accuracy.

Rethinking the Role of the Associate

Contrary to the misconception that automation replaces people, RFID-enabled visibility actually empowers store teams. Associates no longer spend hours on repetitive scanning. Instead, they respond to prioritized insights.

When Badger Technologies’ digital teammates detect an empty space or misaligned item, they alert associates directly. Tasks become proactive, not reactive. Teams can focus on shoppers instead of spreadsheets.

This partnership between people and technology reflects the future of store operations, where associates handle the moments that matter most, supported by automation that never stops working.

The Future Is Continuous

Cycle counts are not disappearing, but they are evolving.

RFID and computer vision have transformed them from a manual, scheduled process into an automated, ongoing capability. Retailers are moving from guessing what is in stock to knowing with confidence, every hour of every day.

Badger Technologies’ next-generation digital teammates help retailers bridge that gap, combining the precision of RFID with the verification power of automation. The result is smarter stores, faster decisions, and a new standard of inventory performance that defines operational excellence.

Citation Notes

- Auburn University RFID Lab – Transforming Retail with RFID, 2023; https://rfid.auburn.edu

- GS1 US – RFID: Transforming Retail, 2023; https://www.gs1us.org

- RFID Journal – Walmart Expands RFID Mandate to Additional Product Categories, 2022; https://www.rfidjournal.com

- Grocery Dive – Kroger Expands RFID Technology to Cut Food Waste, 2023; https://www.grocerydive.com

- Harvard Business Review – RFID: Out of the Box, 2020; https://hbr.org

- ECR Retail Loss Group – Inventory Accuracy and Loss Prevention: A Study of Retail Practices, 2021; https://www.ecrloss.com

- National Retail Federation (NRF) – How Robotics and Automation Empower Retail Associates, 2023; https://nrf.com

- McKinsey & Company – Retail Automation: Efficiency in Every Aisle, 2023; https://www.mckinsey.com

📄 Download the Digital Teammate Fact Sheet (PDF)

Start transforming your store today - schedule a RISK-FREE demo!

About Badger Technologies

Badger Technologies, a product division of Jabil, is a leader in retail automation and artificial intelligence solutions. Its autonomous robots and digital teammates help retailers improve on-shelf availability, pricing accuracy, planogram compliance, and store safety.

With deployments across grocery, building supply, and other high-SKU retail environments, Badger Technologies provides retailers with real-time data and actionable insights that drive measurable results. Headquartered in Nicholasville, Kentucky, the company is committed to helping retailers build smarter, safer, and more efficient stores.